Product Introduction

VJ Technologies (VJT), founded in 1987 in New York, USA, is a leading global provider of X-ray inspection solutions. After more than 30 years of development, in addition to focusing on designing and manufacturing a complete set of industrial CT testing equipment, we also provide the best consulting and training services to users.

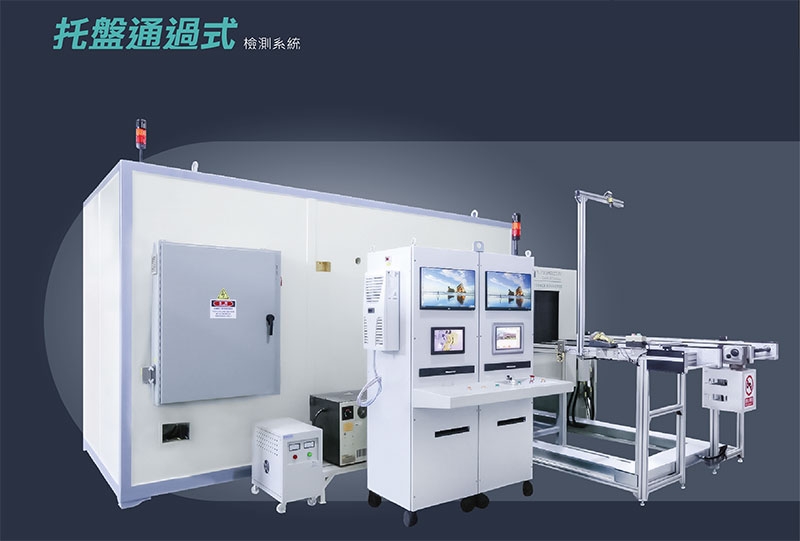

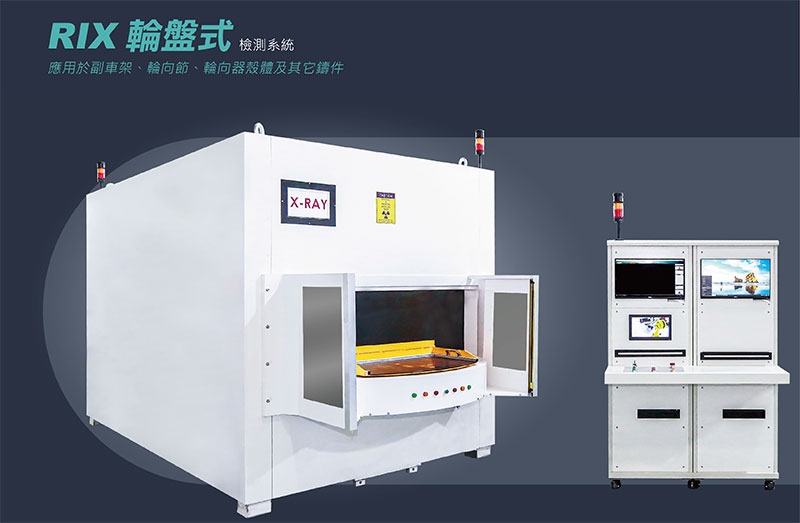

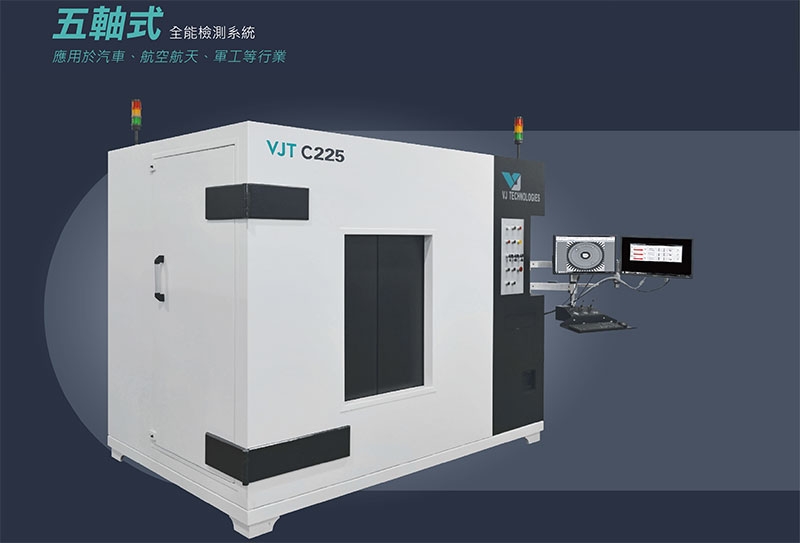

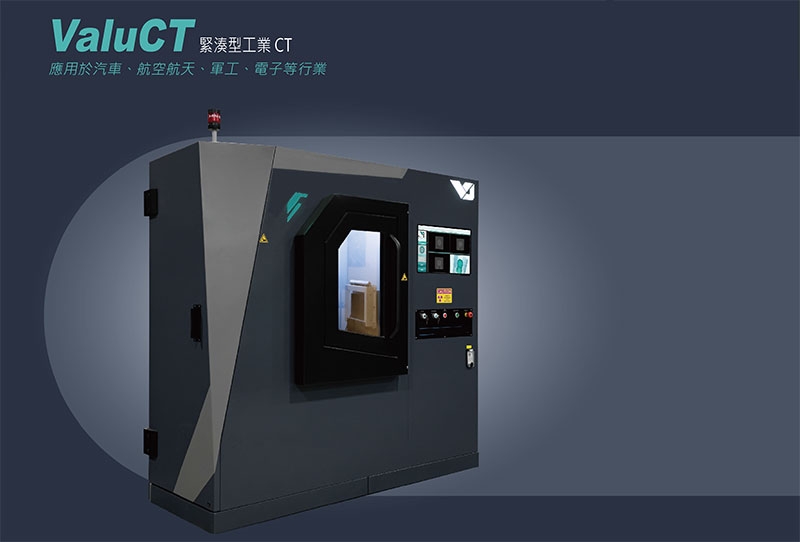

VJT applies X-ray digital imaging technology to the field of non-destructive testing (NDT). VJT can develop and customize a complete set of automated (online), manual (offline) and turnkey X-ray inspection systems according to user needs, including DR (digital imaging) and CT (computed tomography). Used for internal defect detection and analysis of products or parts, or dimensional measurement. Helping users reduce costs and save time while improving quality and safety.

- Auto Parts

- Aluminum alloy wheel joints, subframes, wheel hubs, wheel columns

- Aluminum castings such as engine block, cylinder head, control arm, etc.

- Academic and government institutions

- Academic and government institutions (universities, research institutes, R&D units, etc.)

- Aviation

- Aerospace (engine blades, ducts and other castings or welded parts)

- 3D Printing

- Welding applications (various weld inspections)

- Oil and gas (transportation pipelines)

- Nuclear energy (inspection of intermediate waste from nuclear power plants)

- Composite Materials