Product Introduction

Tinius Olsen was founded in 1880 and is engaged in the manufacture, servicing and calibration of high quality test equipment. With a history of more than 100 years, it is a major manufacturer of tensile material testing machines and compression material testing equipment. The instruments produced are suitable for research and quality control of static material strength and performance. Tinius Olsen instruments can test a wide variety of materials such as metals, polymers, textiles, rubbers, adhesives, foods and finished components. The instrument's test range includes tensile, cutting, compression, bending, puncture/burst, tearing, peeling, melt flow rate, cantilever beam and simply supported beam impact, friction, hardness, heat deformation temperature, Vicat penetration and torsion tests. All tests are carried out in accordance with major testing standards such as ISO, ASTM, EN and other industry standards. For more detailed information, please visit the AiFa website or contact AiFa sales staff for further information.

Based on the popularity and success of the MP600 melt index tester, Tinius Olsen introduces the next generation of revolutionary melt index series - MP1200. The MP1200 is available in two versions, a manual weight system and an electric weight lowering device. The MP1200 incorporates many new features into its design, significantly improving performance, such as:

- Three zone heater

- Touch screen control

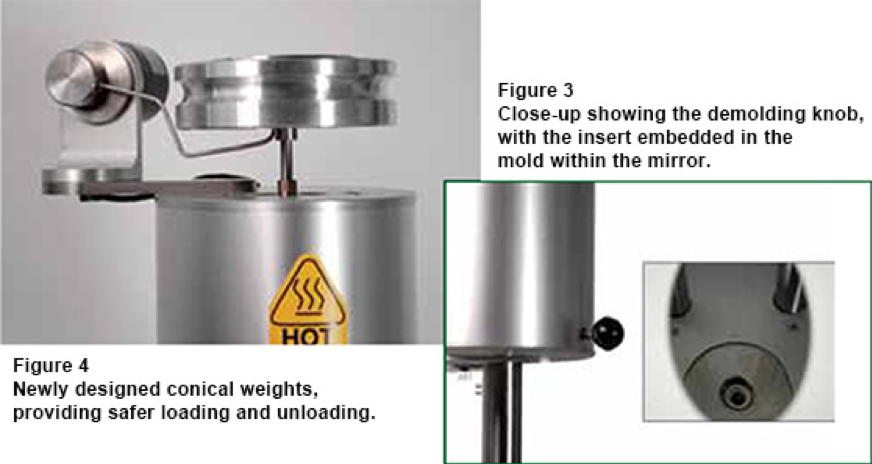

- High efficiency, conical weight design‧Mold release

- USB Connection

- Powerful data analysis and control software

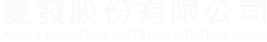

The MP1200 uses a three-zone band heater instead of the more common two-zone band heaters, which increases the temperature stability of the machine. Using 3 platinum RTD temperature sensors, the temperature in the furnace can be maintained to an unprecedented 0.1°C along the test barrel and the maximum allowed temperature variation is 0.1°C. Another new feature introduced in the MP1200 is the use of a touch screen display. The menu's touchscreen-driven range has a similar look and feel to Tinius Olsen's powerful Horizon data analysis and control software. The simple screen set-up quickly sets up the test machine for testing. Once test settings are complete, they can be stored in the MP1200's memory for quick recall. The MP1200 will also maintain an average of the last 25 test runs, allowing for even more complex SPC functionality requirements. The MP1200 can be connected to a PC via a USB cable to run the Horizon software. Horizon will control and collect data from the MP1200 and perform complex SPC analysis, generating reports and control charts as required. Other MP1200 innovations include a demolding system that makes die removal simple and easier to clean; a tapered weight design that provides safer loading and unloading during testing; an optional extrudate cutter that comes with either a manual cutter or a powered cutter; and a built-in reflector that allows the operator to see the extrudate exiting the die, making manual cutting easier.

Figure 1 Semi-automatic MP1200 configured for Program B test

Figure 2 MP1200 configuration program A test

Specifications

| Comply with the specification | ASTM D1238 and D3304, ISO1133-1 and 2, BS 2782, DIN53735, JIS K7210 |

|---|---|

| Operating temperature | Max. 450℃ |

| Temperature control | +/- 0.1℃ |

| Space temperature | +/- 0.1℃ |

| Temperature Controller | Three-zone PID |

| Temperature sensor | Platinum RTD(3) |

| Timer accuracy | 0.001 seconds |

| monitor | 7.1” LCD touch screen, 800x480 resolution |

| Data Entry | Touch screen display |

| Communication Port | USB |

| Weights | Stainless steel, +/- 0.5% accuracy |

| PPDT-1200 Start Switch Sensor Accuracy |

+/- 0.025 mm(+/- 0.001 in) |

| MWLD-1200 automatic weight supports sensor accuracy |

+/- 0.1 mm(+/- 0.01 in) |

| Dimensions | 458mm(18 in)wide x 394 mm(15.5 in)deep x 521 mm(20.5 in)high -base unit or 762 mm (30 in) high -platform lowered to top of weight stand |

| net weight | 21 kg (46 lb) - basic unit or 32 kg (71 lb) –automatic lift unit with weights, without weights or options |

| Gross Weight | 32 kg (70 lb) - basic unit or 43 kg (95 lb) –automatic lift unit with weights, without weights or options |

| power supply | Specify 115 or 230 VAC +/- 10%, 50/60 Hz, ingle phase, 400/800 VA |

| CE marking | Complies with all applicable European CE directives |

Tinius Olsen benchtop materials testing machines can test a wide range of materials. Includes tension, compression, bending or shear of metals, plastics, rubber, textiles, paper, yarn, wire, adhesives, ceramics, wood, foils, composites and finished assemblies. Tension/compression from 1kN (200lbf, 100kg) to 75kN. All tested hardware is fully integrated with software developed by Tinius Olsen to turn your hardware into a complete quality analysis system.

Tabletop ST Series 1 to 50kN (200-11k lbf)

ST Series Floor Standing 100 to 300kN (20 to 60k lbf)

Hydraulic SL Series 150 to 3000kN (30-600k lbf)

Tinius Olsen hydraulic testing equipment has long been recognized as the standard for high accuracy, high reliability and versatility in universal testing machines. Thousands of testers around the world have proven this fact. The SL series now represents the highest standard in hydraulically powered universal testing machines. It uses a patented dual-pressure hydraulic loading system and a sturdy four-post design to enhance the rigidity of the load frame. In addition, it also has a smaller size, a humanized and comfortable working height design, and has a space-saving console. The user interface is freely selectable, including Bluetooth or using a connection port, and all basic tests can be performed in one go via Tinius Olsen's Horizon materials testing software.

Tinius Olsen manufactures impact testers whose pendulums can be easily changed from Charpy to Izod configurations. These testers are available with energies of 406 J, 542 J or 800 J; they are primarily designed for metal impact testing.

All tested hardware is fully integrated with software developed by Tinius Olsen, turning your hardware into a complete quality analysis system. Optional equipment: digital display, power return, low impact clamping device, electronic brake and micro test piece. Technical reference: ASTM E23; ISO 442, ISO 148.

Tinius Olsen has a variety of hardness testers that can quickly and accurately determine the hardness values of a variety of materials, including metals, plastics, large parts, and small precision parts. General series machines are available as follows:

- FH1 Series Desktop

- FH2 Series Desktop

- FH8 Series Desktop

- FH10 Series Desktop

- FH11 Series Desktop

- FH12 Series Floor Standing