Product Introduction

Founded in 1933, LAB Equipment has been recognized for decades as a global leader in the design, manufacture and service of product reliability and assembly test equipment. This includes drop testers, impact testers, hydraulic vibration, mechanical vibration, tilt shock testers.

TrueDrop™ 160

Helps determine the robustness of a package and the effectiveness of its internal cushioning when subjected to impact during material handling. Easily replicate the effects of drops in a lab environment using controlled and precise drop tests on flat surfaces, corners, and edges.

Meets ISTA, ASTM, ISO, MIL STD and other internationally recognized testing standards.

| Feature | Details |

|---|---|

| Payload Capacity | 160 lbs ( 73 kg ) |

| Drop Height | 12-72 in ( 305-1829 mm ) |

| Maximum Package Depth | 32 in ( 813 mm ) |

| Impact Zone | 36x32in ( 914x813 mm ) - WxD |

| Utility Requirement ( Electrical ) | 100-220VAC / 1PH / 50-60Hz 7Amp |

| Utility Requirement ( Air ) | 90 PSI ( 620kPa ) / 2cfm ( 60 lpm ) |

| Machine Weight | 1300 lbs ( 590 kg ) |

| Machine Dimensions | 103x36x69 in ( 2616x914x1753 mm ) - HxWxD |

Due to our continuous commitment to product development, the above specifications and features may be modified without notice.

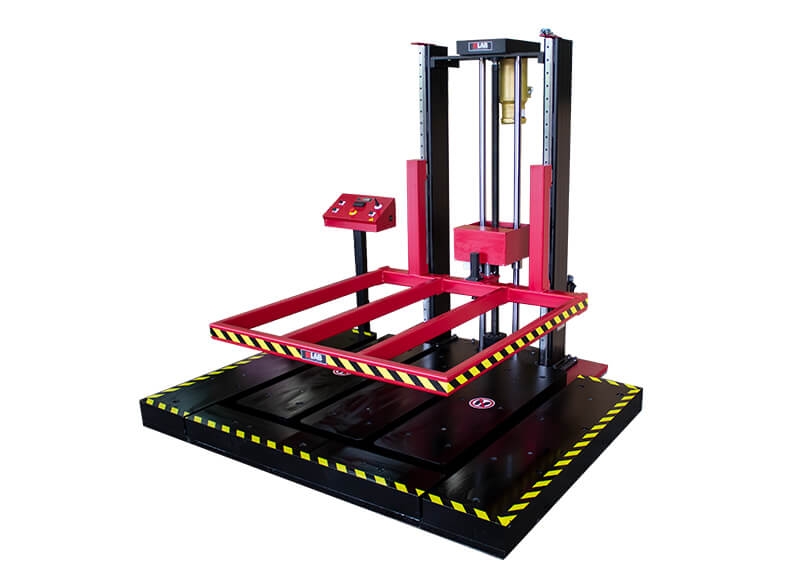

AccuDrop™ 500

Accurate drop testing at an affordable price. We call it the AccuDrop™ 500 Drop Tester. This drop tester represents the ultimate experience in product and package performance testing, designed to meet a variety of global testing needs.

| Feature | Details |

|---|---|

| Payload Capacity | 500 lbs ( 227 kg ) |

| Drop Height | 2-30 in ( 51-762 mm ) |

| Package Size | 30 in ( 762 mm ) - D |

| Impact Zone | 48x30 in ( 1219x762 mm ) -WxD |

| Utility Requirement ( Electrical ) | 220V / 230V / 3PH / 60Hz or 380V / 3PH / 50Hz, 10Amp |

| Machine Weight | 2000 lbs ( 907 kg ) |

| Machine Dimensions | 78x48x44 in ( 2x1.2x1.1mm ) - HxWxD |

AutoShock II™ Automatic Impact Tester

The AutoShock-II ™ is a series of fully automated shock testing systems used to measure and identify the fragility level of products and evaluate protective packaging. By simulating real-world shock pulses, including half-sine, square wave, and sawtooth pulse shapes, as well as shock energy levels, manufacturers can systematically test and optimize product designs and packaging. The fully automatic computer-controlled impact and data analysis test system from Spectral Dynamics Equipment Company of the United States is the key way to achieve this optimization.

SD-Series™ Mechanical Shock Tester

Products need to withstand various shock levels in the operating environment, so they need to be tested in-house during the design and evaluation phases. The SD Series Mechanical Free Fall Test Systems from Spectral Dynamics generate accurate and repeatable half-sine, square wave, and sawtooth pulses to military and industrial specifications.

STM5 Impact Tester

SThe STM5 was developed to meet the impact testing requirements of the small components industry. In the field of production quality control, several machines have been delivered to watch manufacturers and research and development has been carried out.

Specification:

- Max. Payload: 5Kgs

- Max. Repetition Rate 60/minute

- 1/2 Sine Pulse Duration: 0.3 to 25 Msec

- Max. Acceleration: 2000G

- Payload Area: 150 mm Cube

- Shock Input: 3 axis DUT mounting

DAS-105 Version 4

The DAS-105 represents the latest advancement in shock event detection technology. With a high speed, low noise hardware design, and an easy to use software based graphical interface, the DAS-105 is the perfect blend of performance and user convenience.

The DAS-105 represents the latest advancement in resistance sensing technology. Designed with high-speed, low-noise hardware and an easy-to-use software-based graphical interface, the DAS-105 is the perfect combination of performance and user convenience.

TestLab Professional™ Drop/Shock – USB

TLP is a Windows 10 based data acquisition system designed to complement any drop, shock and vibration package test system. TLP accurately captures, analyzes and delivers quantitative results from product and packaging testing. TLP is critical to evaluating the performance of your packaged system in a distribution environment.